DAP Processing Supports the University of Waterloo

Engineering Fatigue Test Lab

Real-Time Feedback Control for Materials Testing

The advent of servo-hydraulic control of materials test machines has, in the last few decades, allowed fatigue researchers to offer a wide variety of new design and evaluation tools to engineers concerned with the cyclic durability of structures. Material fatigue failures can occur after a few or a great many cyclic loads. In the lab efficiencies are achieved by computer control of test waveforms such as proving ground strain or load histories, and by automated and flexible display of the real time test variables. Service history tests can be shortened by a factor of two or more with the introduction high speed servo valves and, accordingly, high speed computer control of the valves. Using a DAP 840 in the control loop has achieved these objectives at the University of Waterloo. [1]

Servo-hydraulic small specimen fatigue test frame and controller [2]

-

Precise control of large hydraulic driving forces is necessary. Responses to measured conditions must be fast and reliable. A few millisecond delay in the response by the computer can easily destroy the test piece and possibly damage the grips, transducers, etc. of the test station as well.

-

Flexibility: adaptation to specialized contract testing and student research programs in both fatigue test lab and structural test labs.

-

Source code: Research students working on experimentally intensive projects need to be able to adjust the control/display programs. Source code for program modules must be easily available, well documented and simple to compile/load.

-

Web User Interface: Graphics, data recording and change of test control variables through

sshconnection and web server processing ofcgi-binpages.

Materials fatigue testing is often done using Servo-hydraulic systems that control the pressure on a hydraulic ram by means of an electrically positioned servo-control valve. The ram pressure or displacement is electronically monitored and used as a feedback control variable to form a closed loop process. Using fast analog-to-digital and digital-to-analog converters, it is possible to insert fast response computer algorithms into the feedback control loop. Fast in a servo-hydraulic system means you can accurately track rapid transitions and perform test cycles at waveform frequencies above 50 Hz.

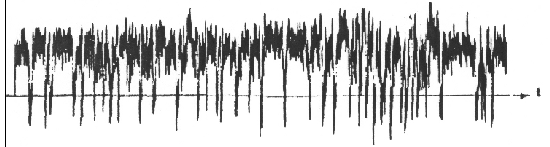

In a typical metal fatigue test, stress amplitude histories from proving ground recordings are "replayed" at waveform speeds of 110 Hz. It is particularly important to track the peaks and valleys closely, and to do this outputs must be maintained consistently in the 10000 to 20000 samples per second range. A temporary computer task swap or interruption of the control program for intervention of some operating system activity could cause process control errors and specimen overload; invalidating the test.

Typical data from a field recording

The primary controller for the hydraulic system is an MTS analog controller. The DAP processor supports the feedback loop by reading analog values, converting them to digital form, applying the control algorithm, and then returning the appropriate command voltage via digital-to-analog converters. At the same time, it acts as an interface between various low-level devices and the high-level process management running on the openSuse 11.2 Linux host.

Click the icon to the left to see a detailed software architecture diagram. Software elements developed for this system included the following:

- mblk10.dap - A configuration script for the DAP board, defining the flow of signals from input devices, through the processing, and to output devices.

- mblk10m.dlm - A downloadable custom processing module defining control functions performed by on-board DAP processing at run-time.

- mterml_sh - A host program developed in C++ to manage the activities of the DAP board, including the initialization and run-time data communications.

- mstun - Small user-interaction programs. These can coordinate with mterml_sh through a shared memory to send commands and receive status information. Accessing one of these over a secured link allows remote monitoring and supervisory control of ongoing experiments over the Internet.

- (others) - Data and status monitoring functions can display test progress information locally, or via Web pages.

"We are using our DAP computers as [an] intelligent function or voltage generator. We are basically monitoring one or two feedback variables with the A/D values and placing a revised command voltage out on the D/A to change the load or strain target voltage. The servo controller's circuits then recognize the change in command voltage and move the servo valve to port extra [hydraulic fluid] to the top or bottom of the hydraulic ram; thus creating changes in the load cell, strain extensometer, or stroke feedback voltages." [3]

- Read more about materials research at the University of Waterloo at the University of Waterloo Fatigue Lab Web site and the University of Waterloo Civil and Environmental Engineering Web site.

- The research for developing this system was supported by NSERC, the Univ. of Waterloo and the Univ. of Windsor, with some assistance and advice from Microstar Laboratories, Inc. The image was provided by the University of Waterloo.

- From the system maintenance manual, with permission from the Engineering Fatigue Test Lab, University of Waterloo.

Browse other application case studies.