Configuring Microstar Laboratories Products for

PID and Control Applications

Configurable Control

(View more Control or Integrated Systems information. Or download preliminary software modules.)

Use the right tool for the job, right? Plain old generic PID controls are perfectly suitable for 95% of control applications, so there is little need to look beyond that — until you encounter the 5% of the control problems that cause 95% of the grief.

|

Control System |

|---|

|

1 MSXB 048, filtered analog input expansion board 2 MSXB 056, analog output expansion board 1 DAPserver test instrument 1 MSCBL 040-01, 68-line round shielded cable 1 MSCBL 054-01, 100-line round shielded cable 1 MSCBL 076-01, 100-line D PC back panel with digital filter adapter board DAPtools Professional CD, including DTD

Contact us to order. |

This note is about how to set up a configurable control system that gives flexibility, power and options when control problems aren't quite so simple as they first appear.

The Motivation

A simple "black box" control component can't be expected to handle every situation perfectly.

- Level dependence. Controls can yield different results at different operating levels.

- External conditions change. Response becomes too sensitive or too sluggish.

- Drive nonlinearity. System responses not proportional in every direction.

- Stability margin. Simple PID controls can worsen a tendency to oscillate.

- Availability. Difficult or expensive to take critical systems offline.

- Conflicting requirements. PID doesn't always give a satisfactory compromise.

- High speed. Hundreds, thousands, tens of thousands of updates per second.

- Multiple channels. Coordinated action.

- Active monitoring, for process optimization or reliability.

Simple encapsulated controls do a few things very well, but nothing more. That seems to be why we have customers who use our products — a lot of them — for their control system applications. Other pages on this site show how the configurability of Data Acquisition Processor (DAP) board systems makes complex solutions possible, and straightforward solutions easy. Maybe an intelligent solution is right for your least cooperative applications.

Data Acquisition Systems for Controls

The first thing you will notice is that "PID Controller" is not listed in our catalogs. That is the nature of our configurable products — they become what you make them. Making them into loop controllers turns out to be relatively easy.

Start with a host. We suggest the DAPserver.

|

The DAPserver serves as a local host, supporting networked communications as needed, and housing all hardware devices, including the host processor, Data Acquisition Processor cards, and the input/output interface cards. The DAPserver 522 model comes with a digital backplane built-in. |

If you already have a suitable host machine for the DAP, you need only add a simple enclosure for the input/output interface cards. You might need some different but functionally equivalent connectors and cables.

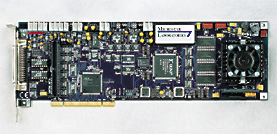

The brains of the operation reside in the Data Acquisition Processor board. The DAP board supplies the analog and digital conversions, timing, data management, communications, and intelligent processing. Its resources are independent of the host, assuring fast and accurate responses every time without fail.

|

For most control applications, we suggest the DAP 5000a/526 model. It has a good blend of data acquisition and processing capabilities, with full floating point support. |

|

However, consider the DAP 5200a/626 model for extra on-board processing power, particularly if your control algorithms require intensive data analysis and matrix mathematics. |

Our technical support staff can help you to evaluate the best balance between capability and economy, but experience has generally shown that demands grow, not shrink, and it is best to avoid being under-powered.

Making Connections

The next task is to configure the input and output channels. Control loops typically require an analog output drive signal and an analog feedback signal. Systems with multiple inputs and outputs simply add additional I/O cards to the rack.

The DAP 5000a or DAP 5200a will support up to 16 input channels without any additional multiplexing boards. These signals are attached at a connector panel, and collected by a MSXB 048 termination card. From there, they are routed to the analog signal connector on the DAP board.

Analog output are expanded by MSXB 056 boards. You will need one expansion board for each four output drive channels. The Data Acquisition Processor board sends the commands for these boards through its digital port connector. A cable connects the Data Acquisition Processor board's digital port to a digital backplane connector on the DAPserver back panel. The backplane then distributes the output commands to the appropriate analog driver cards.

The following illustrates a configuration for 8 input/output pairs. This is easily expanded to 16 input/output pairs by adding two more MSXB 056 boards.

The supervisory commands establishing the setpoint levels

are routed to the Data Acquisition Processor board via the host

bus connector. The setpoint commands can be managed by an

application program running on the host, or by a remote

application operating through standard networking protocols

via the Ethernet connector.

Putting Smarts into the Intelligence

The Data Acquisition Processor board and DAPL operating system work as a team to take care of the important complications that you would rather not worry about.

- How do you operate the converter devices?

- Where do the data come from?

- Where do the results go?

- At what times are the computations needed?

These concerns are all covered. What remains is the unique part of your application that determines, given measurements of your process, what control outputs should be issued.

Unfortunately, there is no completely general answer for

that. Until there is one, you will need a framework that makes

implementing a control strategy easy. One strategy is to start

with a simple processing command such as the PID1

command provided by the DAPL system, and build from there. A

DAPL configuration script for running the control loop might

look something like the following.

PIPE PDRIVE

VARIABLE SETPT = 15800 // Set the command level

IDEFINE INSAMPLES // Configure feedback sampling

CHANNELS 1 // one feedback channel

SET IP0 S0 // unity gain amplifier

TIME 10000 // 1/100 second update interval

END

PDEFINE FEEDBACK // Deliver control outputs

PID1(IP0, SETPT, 3800, 410, 1820, PDRIVE)

DACOUT(PDRIVE,2)

END

The only part that affects the control strategy is the PID1 processing command. To implement a different strategy, substitute a different command.

For example, the

PIDZ command provided on this site adds some

adjustments to control the transfer function zero of classic

PID to improve tracking response. That could be some pretty

tough programming, right? It could be, but it's not.

Using the Developer's Toolkit for DAPL,

the complete runtime

control loop consists of under 30 lines of C++ code. 30 lines

of code should be manageable. Depending on the complexity of

your particular applications, your mileage may vary.

Conclusions

Microstar Laboratories products are "The Intelligent Solution," suitable for problems where an intelligent solution is needed. Such problems exist, as you know very well if you are currently coping with one of them. You will also know that solution alternatives can be hard to find and exceptionally hard to implement. That is not the case with solutions based on Data Acquisition Processor architectures. The infrastructure is all there. The DAP board itself is a measurement testbed, an active prototype, and field-ready implementation platform. The flexibility, configurability, and ease of implementation are unmatched.

Hard to believe? Then don't just believe... prove it to yourself.

Return to the Integrated Systems or Control page.